This is a completely different type of project than the garment and upholstery-type aniline-dyed leather sewing I usually do - it's more along the lines of making a holster, or one of those old-school, molded-leather camera cases.

I'm starting with a piece of 7-8 oz vegetable-tanned leather.

I'm starting with a piece of 7-8 oz vegetable-tanned leather.

It's probably a little heavier than I want for a hood, but this will be a good experiment anyway. If I can make it work with this, the lighter-weight leather should be a breeze.

It's probably a little heavier than I want for a hood, but this will be a good experiment anyway. If I can make it work with this, the lighter-weight leather should be a breeze.

With my digital caliper this piece measured around 2.65 mm in thickness.

With my digital caliper this piece measured around 2.65 mm in thickness.

I'm curious to see if I can use my normal hood pattern on this, or if I am going to need to make a special pattern for the heavier material - a question I hope to answer with this test. I start by rough-cutting after tracing out my pattern shapes.

I'm curious to see if I can use my normal hood pattern on this, or if I am going to need to make a special pattern for the heavier material - a question I hope to answer with this test. I start by rough-cutting after tracing out my pattern shapes.

For the finished cut, I'm using my x-acto knife, leaving around 3/8" for the seam allowance.

For the finished cut, I'm using my x-acto knife, leaving around 3/8" for the seam allowance.

A really sharp blade helps you get a clean cut.

A really sharp blade helps you get a clean cut.

The off-cuts are funny-thick - more like a pile of mini scrap lumber!

The off-cuts are funny-thick - more like a pile of mini scrap lumber!

Now I have my component parts: 2 fronts, 2 backs. No tongue on this one, as the parts would be too thick and ungainly all layered together. Plus, this is just an experiment to see what I can do with the material anyway...

Now I have my component parts: 2 fronts, 2 backs. No tongue on this one, as the parts would be too thick and ungainly all layered together. Plus, this is just an experiment to see what I can do with the material anyway...

I start off clipping the front and rear panels together, as I would with a typical assembly.

I start off clipping the front and rear panels together, as I would with a typical assembly.

In this case, I try to use my cylinder-bed machine, but have no luck getting through the 2-layers of thick leather. I break a few needles before giving up, and just using the machine to punch holes I can use to hand-stitch through.

In this case, I try to use my cylinder-bed machine, but have no luck getting through the 2-layers of thick leather. I break a few needles before giving up, and just using the machine to punch holes I can use to hand-stitch through.

Hand-stitching is slow and tedious work, and really makes you appreciate what (and how fast) your machine can (usually) do.

Hand-stitching is slow and tedious work, and really makes you appreciate what (and how fast) your machine can (usually) do.

Some time later, the hand-stitching is done...

Some time later, the hand-stitching is done...

Now for the fun part. I submerge the leather in a bucket of warm water for about 5 minutes.

Now for the fun part. I submerge the leather in a bucket of warm water for about 5 minutes.

The transformation is noticeable right away. I can actually start to stretch and mold the (now rubbery, softened) leather over the wood head form. It takes some time and muscle, and I keep dunking the leather to help it take the shape.

The transformation is noticeable right away. I can actually start to stretch and mold the (now rubbery, softened) leather over the wood head form. It takes some time and muscle, and I keep dunking the leather to help it take the shape.

After working it for some time, I turn up the edge of the front panels where it comes to meet the rear panels - it's almost like working with clay. To really get some leverage, I need to pull this tight to the form by lacing it on, but first I need to sew the front to the back.

After working it for some time, I turn up the edge of the front panels where it comes to meet the rear panels - it's almost like working with clay. To really get some leverage, I need to pull this tight to the form by lacing it on, but first I need to sew the front to the back.

Because the leather has been softened by the water, I'm now able to run this through my flat-bed machine - most of the way, at least - the top is a problem because of the thickness of those 4 seams (and 8 pieces) coming together.

Because the leather has been softened by the water, I'm now able to run this through my flat-bed machine - most of the way, at least - the top is a problem because of the thickness of those 4 seams (and 8 pieces) coming together.

At this point, I realize that I want to have the smooth leather on the outside, so I rip out all the stitches, and re-sew with the smooth side out. Remember, this is just an experiment, so I don't have to worry about all the holes I already put in along the seams.

At this point, I realize that I want to have the smooth leather on the outside, so I rip out all the stitches, and re-sew with the smooth side out. Remember, this is just an experiment, so I don't have to worry about all the holes I already put in along the seams.

At this point, after another dunking, more molding and hammering, It is really starting to take on the shape of the head form.

At this point, after another dunking, more molding and hammering, It is really starting to take on the shape of the head form.

Now I can put those laces in and get a great amount of pressure on the wet leather.

Now I can put those laces in and get a great amount of pressure on the wet leather.

The contour along the nose and chin are definitely the hardest part. But amazingly - this 7-8 oz leather is taking the shape of the head form.

The contour along the nose and chin are definitely the hardest part. But amazingly - this 7-8 oz leather is taking the shape of the head form.

This is where I left it last night.

This is where I left it last night.

And 24 hours later, I have this hardened, dry shell:

And 24 hours later, I have this hardened, dry shell:

As you can see the water has mostly evaporated out, so the color is much lighter.

As you can see the water has mostly evaporated out, so the color is much lighter.

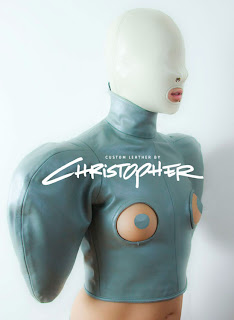

When I manage to ease the hood off of the form, it holds its shape extremely well. It's very stiff. And the best news: it fits the model. Perfectly!!

When I manage to ease the hood off of the form, it holds its shape extremely well. It's very stiff. And the best news: it fits the model. Perfectly!!

I need to work out a good way to stitch this type of piece, but for now I consider the experiment a success... There are a lot of ways I can finish this leather - from an oil-coat brown to shiny black or even paint with colors. I could even do tooling or stamped designs...

I need to work out a good way to stitch this type of piece, but for now I consider the experiment a success... There are a lot of ways I can finish this leather - from an oil-coat brown to shiny black or even paint with colors. I could even do tooling or stamped designs...

The seam allowances on this hood would definitely be part of the look, although I plan on shaving them down and finishing the edges a lot more than they are now. I may even continue to wet and stretch to see how far I can go. I need to try this with some 4-5 oz leather as well...

The seam allowances on this hood would definitely be part of the look, although I plan on shaving them down and finishing the edges a lot more than they are now. I may even continue to wet and stretch to see how far I can go. I need to try this with some 4-5 oz leather as well...

For now, I'm putting her back on the form to finish drying out completely...

For now, I'm putting her back on the form to finish drying out completely...

I'm starting with a piece of 7-8 oz vegetable-tanned leather.

I'm starting with a piece of 7-8 oz vegetable-tanned leather.  It's probably a little heavier than I want for a hood, but this will be a good experiment anyway. If I can make it work with this, the lighter-weight leather should be a breeze.

It's probably a little heavier than I want for a hood, but this will be a good experiment anyway. If I can make it work with this, the lighter-weight leather should be a breeze. With my digital caliper this piece measured around 2.65 mm in thickness.

With my digital caliper this piece measured around 2.65 mm in thickness.  I'm curious to see if I can use my normal hood pattern on this, or if I am going to need to make a special pattern for the heavier material - a question I hope to answer with this test. I start by rough-cutting after tracing out my pattern shapes.

I'm curious to see if I can use my normal hood pattern on this, or if I am going to need to make a special pattern for the heavier material - a question I hope to answer with this test. I start by rough-cutting after tracing out my pattern shapes.  For the finished cut, I'm using my x-acto knife, leaving around 3/8" for the seam allowance.

For the finished cut, I'm using my x-acto knife, leaving around 3/8" for the seam allowance.  A really sharp blade helps you get a clean cut.

A really sharp blade helps you get a clean cut.  The off-cuts are funny-thick - more like a pile of mini scrap lumber!

The off-cuts are funny-thick - more like a pile of mini scrap lumber! Now I have my component parts: 2 fronts, 2 backs. No tongue on this one, as the parts would be too thick and ungainly all layered together. Plus, this is just an experiment to see what I can do with the material anyway...

Now I have my component parts: 2 fronts, 2 backs. No tongue on this one, as the parts would be too thick and ungainly all layered together. Plus, this is just an experiment to see what I can do with the material anyway... I start off clipping the front and rear panels together, as I would with a typical assembly.

I start off clipping the front and rear panels together, as I would with a typical assembly.  In this case, I try to use my cylinder-bed machine, but have no luck getting through the 2-layers of thick leather. I break a few needles before giving up, and just using the machine to punch holes I can use to hand-stitch through.

In this case, I try to use my cylinder-bed machine, but have no luck getting through the 2-layers of thick leather. I break a few needles before giving up, and just using the machine to punch holes I can use to hand-stitch through.  Hand-stitching is slow and tedious work, and really makes you appreciate what (and how fast) your machine can (usually) do.

Hand-stitching is slow and tedious work, and really makes you appreciate what (and how fast) your machine can (usually) do.  Some time later, the hand-stitching is done...

Some time later, the hand-stitching is done... Now for the fun part. I submerge the leather in a bucket of warm water for about 5 minutes.

Now for the fun part. I submerge the leather in a bucket of warm water for about 5 minutes.  The transformation is noticeable right away. I can actually start to stretch and mold the (now rubbery, softened) leather over the wood head form. It takes some time and muscle, and I keep dunking the leather to help it take the shape.

The transformation is noticeable right away. I can actually start to stretch and mold the (now rubbery, softened) leather over the wood head form. It takes some time and muscle, and I keep dunking the leather to help it take the shape.  After working it for some time, I turn up the edge of the front panels where it comes to meet the rear panels - it's almost like working with clay. To really get some leverage, I need to pull this tight to the form by lacing it on, but first I need to sew the front to the back.

After working it for some time, I turn up the edge of the front panels where it comes to meet the rear panels - it's almost like working with clay. To really get some leverage, I need to pull this tight to the form by lacing it on, but first I need to sew the front to the back.  Because the leather has been softened by the water, I'm now able to run this through my flat-bed machine - most of the way, at least - the top is a problem because of the thickness of those 4 seams (and 8 pieces) coming together.

Because the leather has been softened by the water, I'm now able to run this through my flat-bed machine - most of the way, at least - the top is a problem because of the thickness of those 4 seams (and 8 pieces) coming together.  At this point, I realize that I want to have the smooth leather on the outside, so I rip out all the stitches, and re-sew with the smooth side out. Remember, this is just an experiment, so I don't have to worry about all the holes I already put in along the seams.

At this point, I realize that I want to have the smooth leather on the outside, so I rip out all the stitches, and re-sew with the smooth side out. Remember, this is just an experiment, so I don't have to worry about all the holes I already put in along the seams.  At this point, after another dunking, more molding and hammering, It is really starting to take on the shape of the head form.

At this point, after another dunking, more molding and hammering, It is really starting to take on the shape of the head form.  Now I can put those laces in and get a great amount of pressure on the wet leather.

Now I can put those laces in and get a great amount of pressure on the wet leather.  The contour along the nose and chin are definitely the hardest part. But amazingly - this 7-8 oz leather is taking the shape of the head form.

The contour along the nose and chin are definitely the hardest part. But amazingly - this 7-8 oz leather is taking the shape of the head form. This is where I left it last night.

This is where I left it last night.  And 24 hours later, I have this hardened, dry shell:

And 24 hours later, I have this hardened, dry shell: As you can see the water has mostly evaporated out, so the color is much lighter.

As you can see the water has mostly evaporated out, so the color is much lighter. When I manage to ease the hood off of the form, it holds its shape extremely well. It's very stiff. And the best news: it fits the model. Perfectly!!

When I manage to ease the hood off of the form, it holds its shape extremely well. It's very stiff. And the best news: it fits the model. Perfectly!! I need to work out a good way to stitch this type of piece, but for now I consider the experiment a success... There are a lot of ways I can finish this leather - from an oil-coat brown to shiny black or even paint with colors. I could even do tooling or stamped designs...

I need to work out a good way to stitch this type of piece, but for now I consider the experiment a success... There are a lot of ways I can finish this leather - from an oil-coat brown to shiny black or even paint with colors. I could even do tooling or stamped designs... The seam allowances on this hood would definitely be part of the look, although I plan on shaving them down and finishing the edges a lot more than they are now. I may even continue to wet and stretch to see how far I can go. I need to try this with some 4-5 oz leather as well...

The seam allowances on this hood would definitely be part of the look, although I plan on shaving them down and finishing the edges a lot more than they are now. I may even continue to wet and stretch to see how far I can go. I need to try this with some 4-5 oz leather as well... For now, I'm putting her back on the form to finish drying out completely...

For now, I'm putting her back on the form to finish drying out completely...